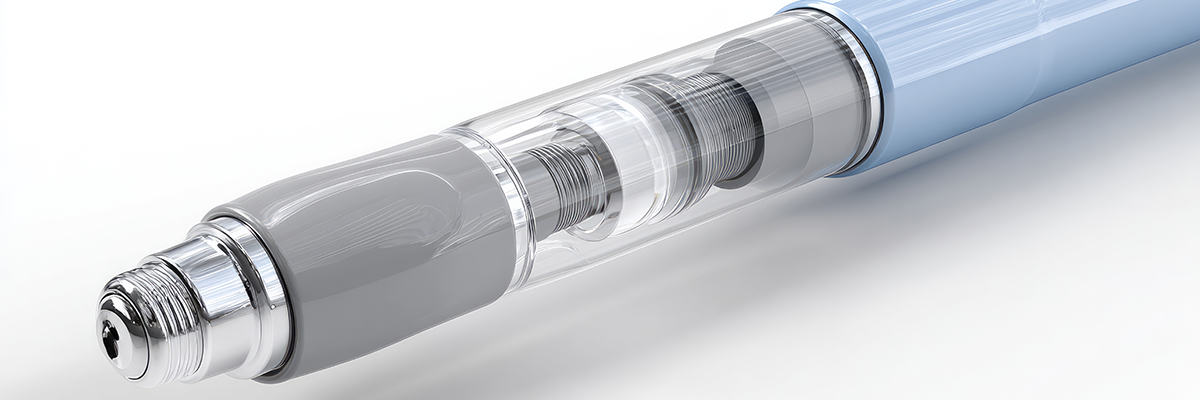

When a global manufacturer of transparent medical components needed to reduce waste from false rejects while improving defect detection rates, EZ Automation’s EZ Eye platform delivered production-speed inspection that dramatically improved both quality and efficiency. The Problem A leading global manufacturer of transparent medical components confronted a dual challenge in its quality assurance operations: It strove to minimize the number of defective products reaching customers while also minimizing waste from false rejects. With annual production volumes in the billions, even small improvements to either metric would translate to a significantly positive financial impact. The manufacturer’s existing quality assurance approach relied on statistical sampling that proved inadequate for modern production demands. The inspection system struggled to distinguish between legitimate defects — such as foreign matter, scratches, and packaging irregularities — and acceptable optical variations in the product. As a consequence, false positive defect detections sent acceptable products to waste, while defects that escaped detection generated customer complaints, threatening the company’s reputation for quality and reliability. The manufacturer set aggressive improvement targets: reduce customer complaints by 80% while simultaneously minimizing waste from false rejections. It further aimed to achieve these goals within an extremely tight inspection cycle time of 40 milliseconds per unit to maintain throughput. The Solution The manufacturer implemented EZ Automation’s EZ Eye machine vision platform as a smart inspection solution capable of examining every unit at production speed while maintaining the accuracy required for regulated medical device applications. EZ Eye’s deep learning architecture employs convolutional neural networks trained to recognize subtle patterns to distinguish genuine defects from acceptable product variations. EZ Eye’s active learning methodology is central to this capability as it continuously refines detection accuracy based on compiled operational data. The system identifies low-confidence classifications and routes those images to quality engineers for expert review, allowing it to generate progressively more robust training data while ensuring that critical quality decisions remain under expert oversight. To address the limited availability of real-world defect samples, the platform leverages synthetic data augmentation techniques to create realistic defect examples and insert them into authentic production images to build comprehensive training datasets. The resulting inspection system synthesizes outputs from multiple neural networks to deliver final quality determinations with exceptional reliability. The Benefits Deployment of the EZ Eye platform across the manufacturer’s production operations delivered measurable improvements in both quality and efficiency:

- Waste Reduction: The manufacturer significantly reduced false rejection rates to improve yield and ensure that acceptable products reached customers.

- Quality Improvement: Customer complaint rates dropped dramatically as the system’s ability to detect legitimate defects — including foreign matter as small as 300 microns — exceeded the capabilities of previous inspection methods.

- Production Integration: EZ Automation’s platform successfully met the demanding 40 millisecond inspection cycle requirement, enabling every unit to receive comprehensive quality assessment without impacting production throughput.

- Enterprise Scalability: Following validation on pilot production lines, the manufacturer expanded EZ Eye’s deployment to dozens of lines, demonstrating the platform’s ability to deliver consistent performance across different sites and product variations.

- Continuous Improvement: EZ Eye’s active learning architecture ensures that inspection accuracy continues to improve over time as the system incorporates data from new defect types and production variations to become more robust with operational experience.

The successful implementation of EZ Automation’s EZ Eye helped the manufacturer maintain its competitive position in an increasingly demanding market while optimizing resource utilization across global operations.