Web manufacturing demands uncompromising quality control at high speeds. A single undetected defect in continuous materials like films, foils, paper, textiles, or metal panels can result in costly waste, customer rejections, and production downtime. Manual sampling and offline inspection cannot keep pace with high-speed production lines or provide the 100% coverage required to ensure consistent quality.

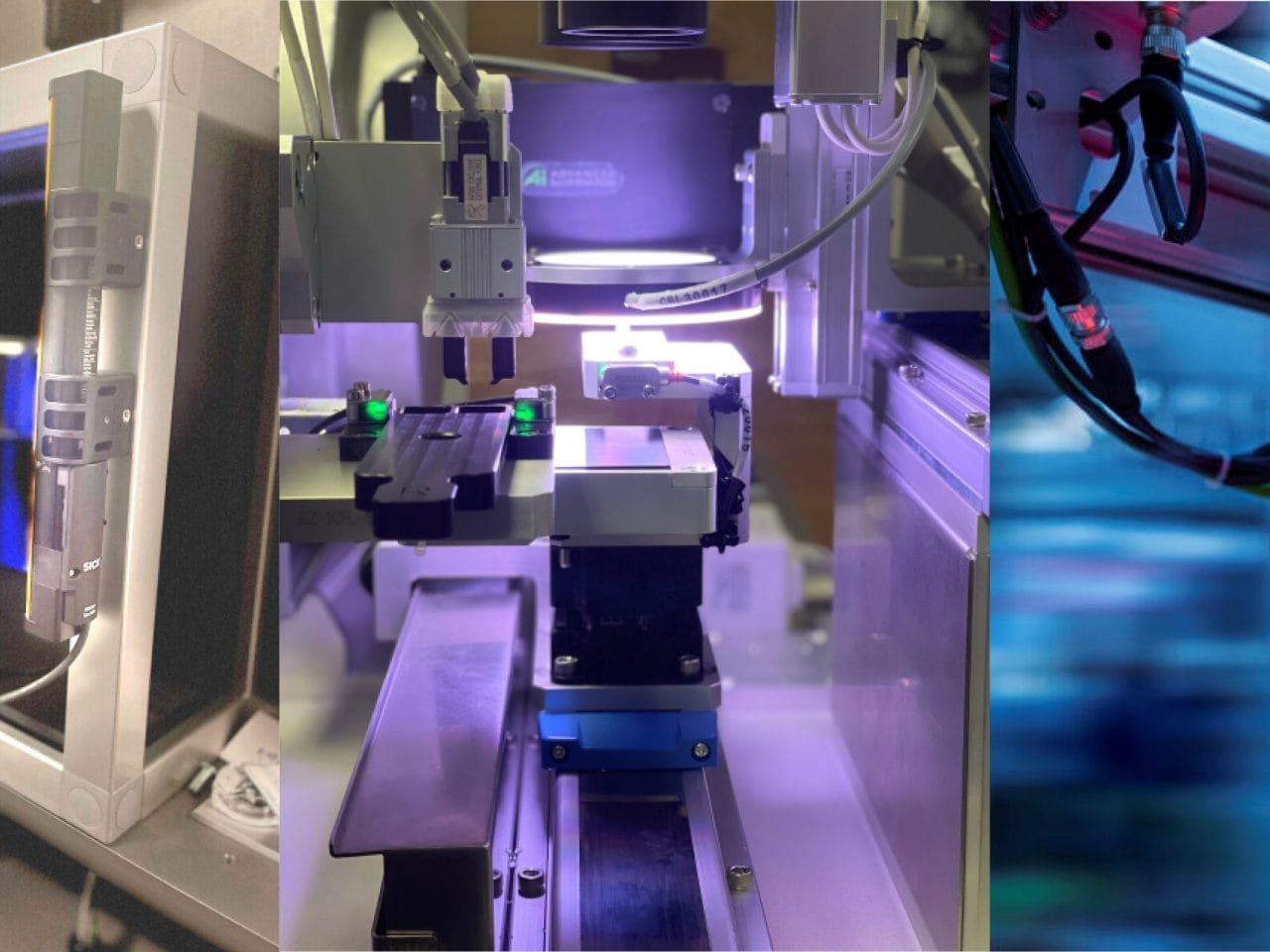

EZ Automation Systems designs turnkey AI-powered inspection solutions specifically for high-speed web manufacturing processes. Whether you produce flexible packaging materials, battery components, flooring products, or industrial textiles, our systems deliver real-time defect detection across the entire web width at production speeds up to 100 ft/min, identifying flaws as small as 0.1 mm.

Our multidisciplinary team includes AI and computer vision engineers who develop adaptive inspection algorithms, automation specialists who integrate systems seamlessly with existing production lines, and optics experts who optimize imaging for diverse material characteristics.

Our Web Inspection Capabilities

- Continuous Surface Inspection: Scratches, dents, wrinkles, pinholes, and surface contamination

- AI-Powered Defect Classification: Adaptive AI algorithms improve on each inspection cycle to distinguish acceptable variations from true defects and minimize false rejects

- Customizable Architecture: Configurable camera arrays, lighting, and optics are tailored to your inspection parameters and line speed — from narrow web to wide-format production

- Seamless Integration: Our solutions interface easily with existing PLCs, SCADA, or MES systems to trigger alarms, mark defects, generate reports, or adjust process parameters in real time

- Data-Driven Insights: EZ’s custom centralized dashboard enables intuitive defect trend analysis, batch reporting, and predictive maintenance to support continuous process improvement

Our systems are built for flexibility, scalability, and intelligence. Whether you’re optimizing an existing line or designing a new one, EZ Automation’s inspection solutions adapt to your process, not the other way around. From conceptual design to deployment and support, we deliver an end-to-end solution that elevates production efficiency and product reliability within eight weeks. What other benefits can you expect?

- Higher Throughput: Inline, high-speed, AI-driven web inspection eliminates manual checking bottlenecks

- Improved Yield: Early detection of defects prevents waste and reduces downstream rework

- Enhanced Traceability: Each defect is logged with position, type, and a time stamp for root cause analysis

- Rapid ROI: Scalable platforms minimize downtime, improve quality consistency, and ensure compliance with ISO and customer quality standards

Manufacturing Applications We Support

- Carpet Flooring Inspection: Pattern consistency, color matching, and surface defect detection

- Turf Panel Inspection: Fiber density verification, backing integrity, and appearance uniformity

- Wood Panel Inspection: Grain pattern analysis, knot detection, and surface quality assessment

- Metal Panel Inspection: Surface finish verification, coating uniformity, and corrosion detection

- Mesh Sheet Inspection: Weave pattern consistency, hole size verification, and surface contamination

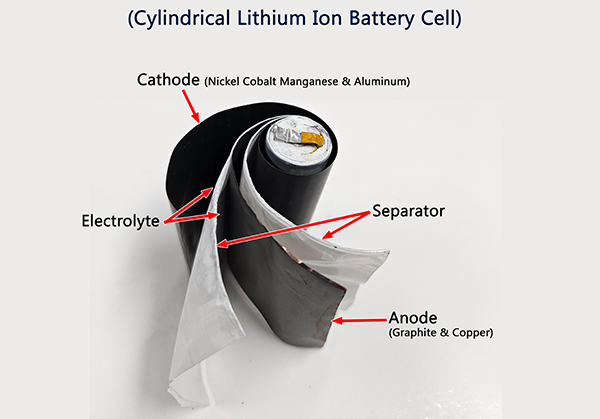

- Battery Foil Inspection: Pinhole detection, thickness uniformity, and surface cleanliness critical for battery performance

- Cable Inspection: Insulation integrity, diameter consistency, and surface defect identification

Featured Solutions for Web Inspection

Web manufacturing involves diverse material types with unique inspection challenges. The EZ Eye platform enables rapid development of custom AI inspection models tailored to your specific materials and defect criteria, reducing deployment time and adapting quickly to process variations or new product introductions.

PIQuE-360 is our standalone robotic inspection platform designed for 360-degree AI-powered inspection of medical devices and components. It delivers over 95% defect detection accuracy, zero false positives after initial calibration, and significantly faster training of AI models.