Aerospace manufacturing requires absolute precision. Even a microscopic defect, misaligned component, or imperfect coating can compromise safety and result in costly scrap or rework. Manual inspection methods often cannot keep up with increasing production volumes, complex geometries, and stricter quality standards.

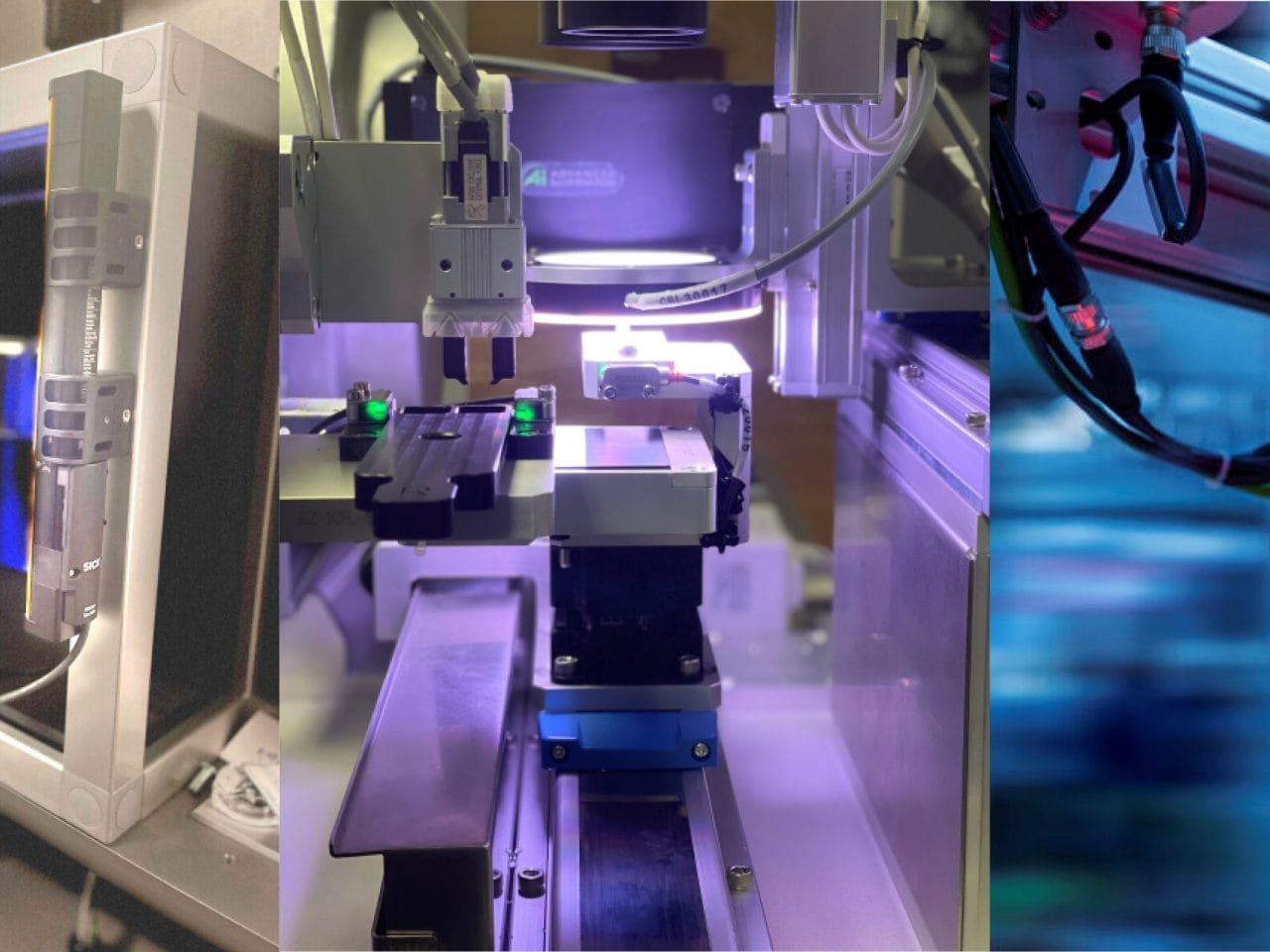

EZ Automation Systems designs turnkey automated inspection solutions for aerospace component manufacturers and suppliers. Whether you produce avionics assemblies, engine components, rotating parts, or apply critical surface coatings, our systems use advanced machine vision, AI-powered defect detection, and seamless production line integration to ensure every part meets aerospace quality standards.

Our multidisciplinary team includes AI and computer vision engineers who develop both rule-based and deep learning inspection models. Robotics and automation specialists integrate inspection systems with production workflows. Optics and imaging experts optimize illumination for challenging materials, including reflective turbine blades and complex PCB assemblies.

Our Aerospace Inspection Capabilities

- Dimensional Metrology

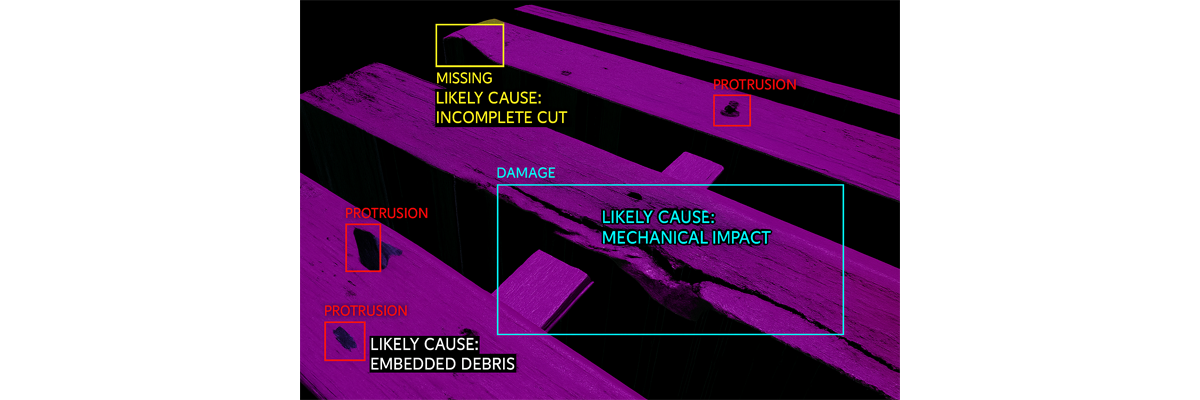

- Surface Defect Detection

- Assembly Verification

- Material and Treatment Validation

- Part Identification and Traceability

Why Aerospace Component Suppliers Choose EZ Automation

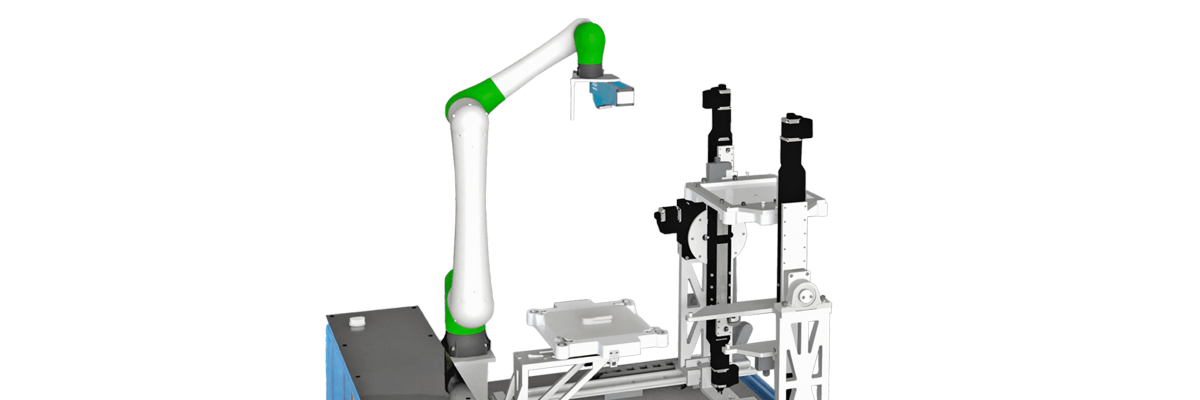

Turnkey Automation Systems

We provide complete inspection solutions that integrate vision technology, robotic systems, PLCs, and MES platforms for end-to-end automation. Our team manages every stage, from application assessment and system design to installation, validation, operator training, and ongoing technical support. You receive a unified solution focused on performance, traceability, and compliance.

Technology-Agnostic Machine Vision Integration

From camera and lighting selection to software development and AI model training, we engineer systems tailored to your specific application. We integrate leading platforms such as Nvidia HALCON, Cognex VisionPro, PyTorch, OpenCV, and MATLAB, selecting or developing the right combination of tools instead of applying a one-size-fits-all approach.

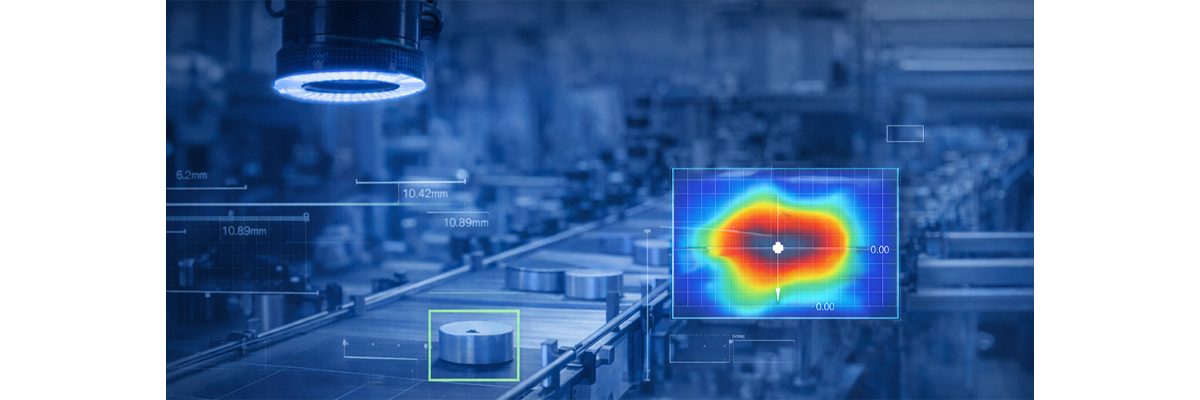

Hybrid Inspection Architecture

Our approach combines deep learning tools with the reliability and transparency of rules-based machine vision. This hybrid methodology allows full transparency in defect reasoning, real-time data collection, inspection analytics for performance tracking, and audit-ready documentation.

Rapidly Reconfigurable Automation

Our systems can be reconfigured for new part types within hours, not days or weeks, to support the flexibility you require and still deliver high-accuracy inspection.

Scaled to Your Needs

EZ Automation works closely and collaboratively with small-, medium-, and enterprise-scale manufacturers to engineer advanced AI-driven inspection systems tailored to the customer’s operational goals and budget

Aerospace Inspection Applications We Support

Avionics and Electronics

- 3D solder joint inspection and component placement verification

- Automated PCB board and connector inspection

- Small defect detection using AI models built in PyTorch and MATLAB

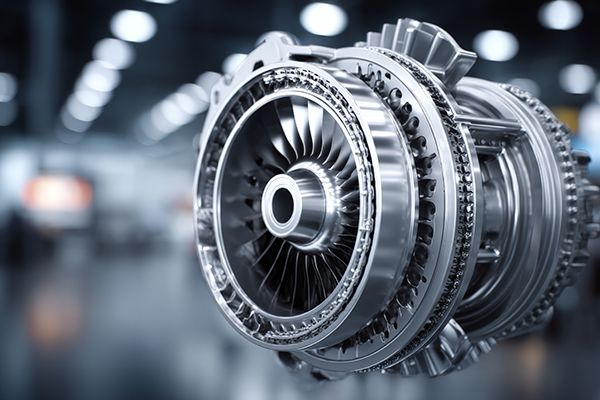

Engines and Rotating Parts

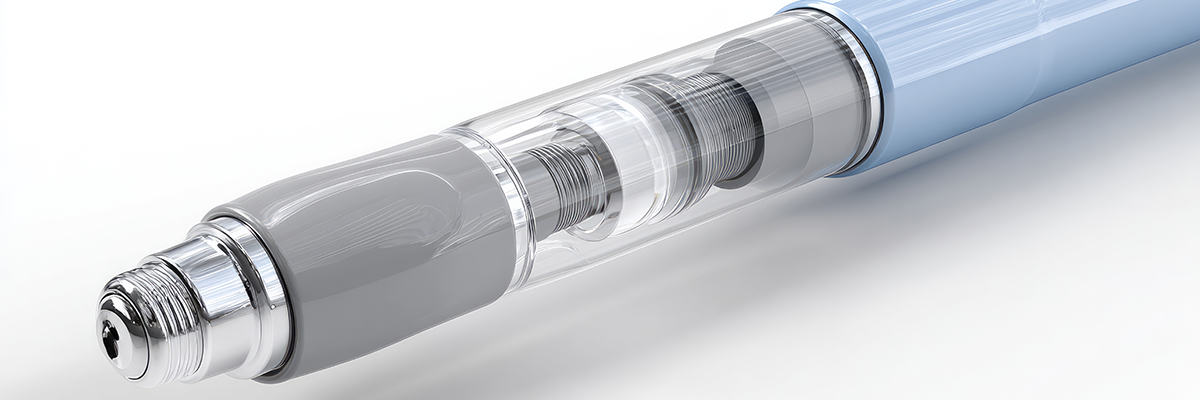

- Blade edge and surface wear inspection at micron-level precision

- Shape and fit verification for 2D and 3D metrology

Surface Treatments and Coatings

- Paint and coating thickness verification

- Detection of corrosion, scratches, pitting, or uneven surface finishes

Traceability and Documentation

- OCR and barcode reading for part identification and serialization

- Automatic data logging and reporting for AS9100 compliance

- Dashboards for tracking inspection performance and part history in real-time

Featured Solutions for Aerospace Inspection

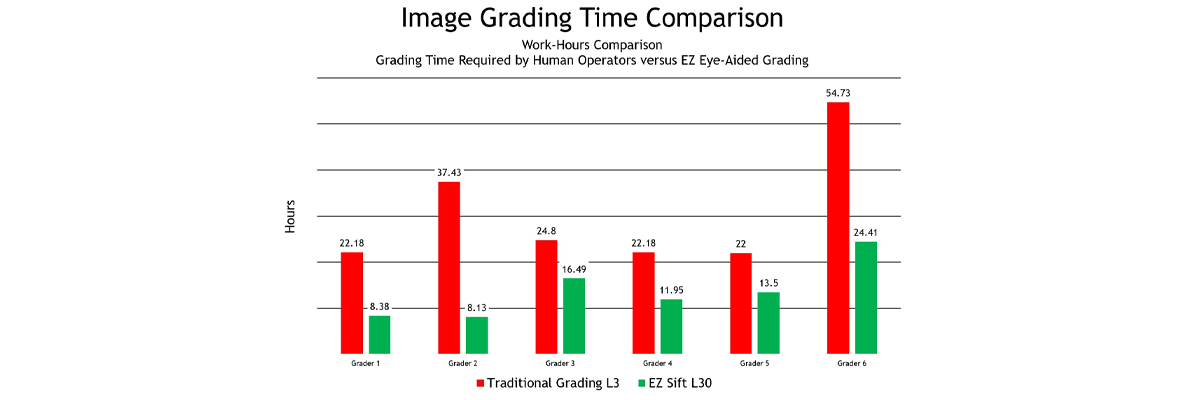

Aerospace manufacturing involves a wide range of component geometries and defect types. The EZ Eye platform enables rapid development of custom AI inspection models tailored to your specific parts and quality requirements.

PIQuE-360 is our standalone robotic inspection platform designed for 360-degree AI-powered inspection of aerospace components and systems. It delivers over 95% defect detection accuracy, zero false positives after initial calibration, and significantly faster training of AI models.